Rommelag Engineering GmbH

Booth number: H3.D18

www.rommelag.com

About us

Rommelag is the inventor and global leader in aseptic filling systems using Blow-Fill-Seal (BFS) technology. Our bottelpack packaging systems are considered advanced aseptic filling by regulatory authorities. The BFS containers are formed from plastic polymer material in an automated process, filled and hermetically sealed. With its BFS packaging solutions for sterile liquids (e.g. eye drops, infusion solution, injectables, inhalations, vaccines), gels and ointments, Rommelag is present in the pharmaceutical, healthcare, but also in the cosmetic as well as the chemical industries.

Key applications of the BFS technology are bottles, ampoules, bellows and dropper bottles which can be produced in various shapes and types of plastic. bottelpack systems produce up to 30,000 containers per hour. Typical container volumes range from less than 0.1 ml to more than 1,000 ml.

Rommelag Engineering offers a system configuration tailored to the product. We complement our bottelpack lines with inspection systems and digitalisation solutions.

Being a one-stop partner, Rommelag supports their customers with in-house Pharma Service from the planning phase through validation and qualification to plant optimisation.

Our after-sales service sustains throughout the entire product life cycle: from installing the plant system by our technicians to its maintenance, repair and complex modifications. With attractive service packages, we ensure that the investment in a bottelpack system pays off. We prevent unplanned downtimes and optimise plant performance.

Address

Talstrasse 22-30

74429 Sulzbach-Laufen

Germany

E-mail: mail.reg@rommelag.com

Phone: +49 7976 80-0

Internet: www.rommelag.com

Contact person:

Maklawe Batema

Area Sales Manager

E-mail: maklawe.batema@rommelag.com

Products & Services

Blow-Fill-Seal is considered one of the most advanced methods of aseptic processing, as it is fully automated without any manual intervention. This is also supported by various medicine regulatory agencies including the U.S. Food and Drug Administration (FDA) in the packaging of pharmaceutical and healthcare products.

Approved by regulatory bodies (EMA & FDA)

Recognized advanced aseptic process (USP 1116)

Maximum safety thanks to ISO Class 5 conditions

The perfect choice for even sensitive formulations

Modular design for easy separation into grey and white plant zone

Automatic execution of required cleaning and sterilisation processes

significantly reduces human intervention in the packaging process, minimising the risk of physical and microbial contamination.

Output volumes up to 34,000 pieces per hour

bottelpack Advanced Aseptic Filling Systems

If it says “bottelpack” on it, you can rely on the uncompromisingly good quality offered by the inventor of Blow-Fill-Seal Technology. bottelpack machines can manufacture up to 34,000 containers an hour in a wide variety of forms and plastic blends, with filling volumes ranging from less than 0.1 to more than 1,000 ml.

ADVANCED ASEPTIC AMPOULE FILLING: BFS Closed Parison Technology is flexibility on a small footprint, combined with highest sterility assurance, which fullfils the new Annex 1 EU GMP guideline.

Container design

Our bottelpack aseptic packaging systems are considered advanced aseptic filling by regulatory authorities. The BFS containers are formed from plastic polymer material in an automated process, filled and hermetically sealed. With the packaging of sterile liquids (e.g. eye drops, infusion solution, injectables, inhalations, vaccines), gels and ointments, Rommelag is present in pharmaceutical, healthcare, and also in cosmetic and chemical industries.

With Blow-Fill-Seal Technology, bottles, ampoules, dropper bottles, bellows containers can be produced in various shapes and types of plastic. bottelpack lines produce up to 34,000 containers/hour.

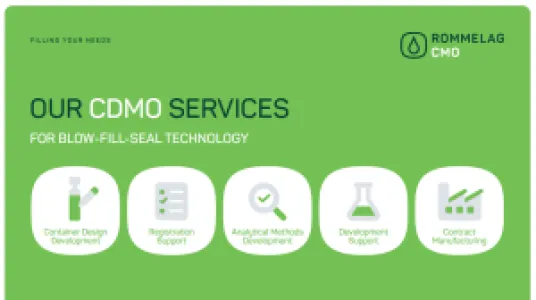

CDMO Services

CDMO is your fastest and easiest way to access BFS technology. It's particularly economical for test fillings, market batches or very small series. No matter what the industry, liquid or semi-solid, we support you from the initial idea through design to contract filling and packaging at the highest standards.